Superabrasive

Diamond Tools & Equipment

Superabrasive – Lavina

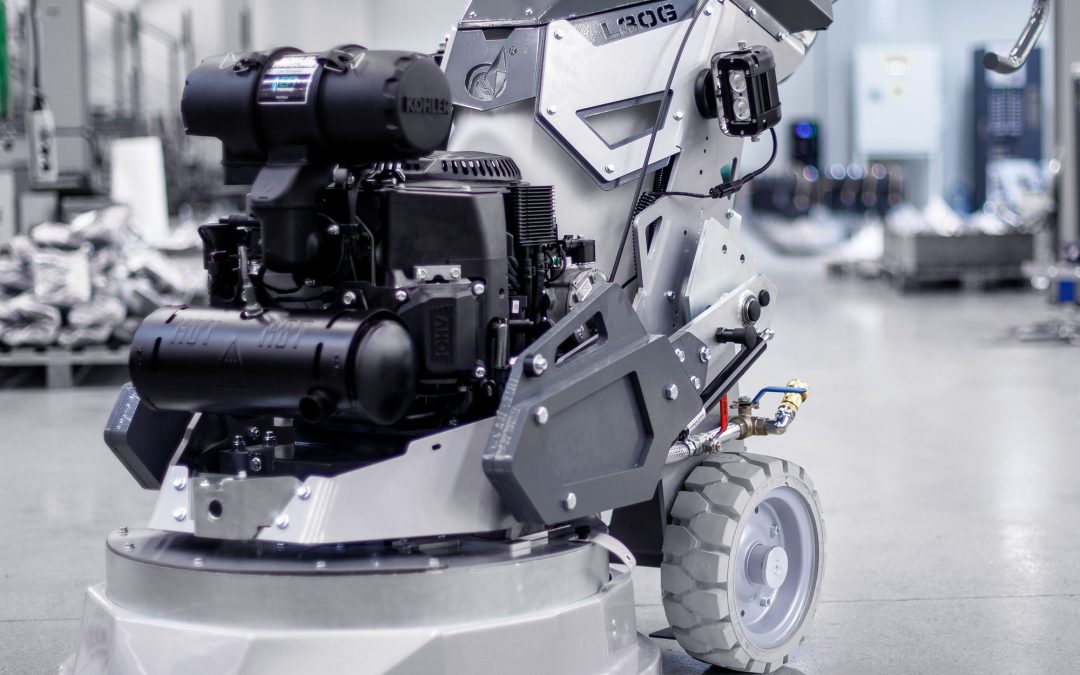

Superabrasive diamond tools and equipment set the industry standard for precision, durability, and efficiency across demanding industrial applications. Engineered with advanced diamond abrasives, our tools excel in the most challenging tasks—grinding, polishing, cutting, and honing—delivering superior speed and consistent results.

Whether you’re working in concrete and stone fabrication, metalworking, or floor preparation, Superabrasive products provide extended tool life, minimize downtime, and produce exceptional surface finishes that drive higher productivity while reducing your total operating costs.

Product Lineup

Superabrasive & Lavina Technology

Superabrasive / Lavina FAQ

What is Lavina equipment used for?

Lavina machines are used for grinding, polishing, and surface preparation of concrete, stone, terrazzo, and overlays. Applications include floor restoration, coating removal, leveling, and high-gloss polishing.

Did Superabrasive acquire Lavina?

Lavina is a brand developed and owned by Superabrasive since its inception, first introduced in 2004 as the company’s in-house line of concrete grinding and polishing machines. Since then, Superabrasive has continuously expanded the Lavina product line with innovative upgrades and new series, including the SPS in 2008, Pro in 2010, S in 2013, X in 2017, Elite in 2019, and the latest S7 series in 2023.

LabSurface PDF | click here

What makes Lavina grinders different from other brands?

Lavina grinders feature innovative planetary drive systems, dust-sealed heads, and a Quick Change Tooling System for fast tool swaps. They are built for durability, precision, and reduced maintenance downtime, making them ideal for both large-scale industrial jobs and precision polishing tasks.

What sizes and models are available?

Lavina offers a full range of models, from propane and electric walk-behind grinders (20"–38") to ride-on models for large-scale commercial projects. Models are grouped into series like S7, Elite, X, and ECO, each designed for specific applications and user needs.

Can Lavina grinders be used for both wet and dry applications?

Yes, Lavina machines can be used for both wet and dry grinding and polishing. Many models include features like water tanks and vacuum ports for integrated dust control.

What types of tools are compatible with Lavina machines?

Lavina equipment is compatible with a wide range of metal bond, resin bond, hybrid, and transitional tools, as well as tools for coating removal, polishing, and honing. This includes 515's in-house brand of UFO diamond tools.

What maintenance is required for Lavina grinders?

Regular maintenance includes cleaning dust seals, checking belts and chains, lubricating moving parts, and inspecting electrical or fuel systems. Models are designed for easy maintenance with accessible components. 515 can maintenance and repair Lavina equipment.